Foshan Luzhou Pu Machinery Co.,ltd

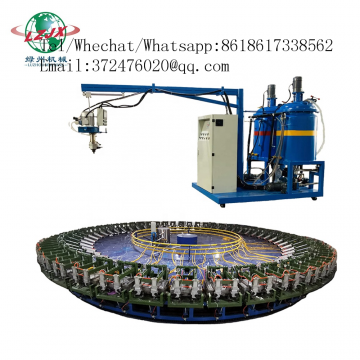

Main Products: PU FOAMING MACHINE WITH PRODUCTION LINE, PU OUTSOLE FOAMING MACHINE WITH PRODUCTION LINE, PU INSOLE FOAMING MACHINE, PRODUTION LINE FOR PU BICUCLE SEAT CUSHIONS, PRODUCTION LINE FOR MOTORCYCLE SEAT CUSHIONS, HIGH PRESSURE FOAMING MACHINE, COLOR STEEL TILE FOAMING PRODUCTION LINE, PU PRODUCTION MACHINE FOR SHOE EAR PLUGS

Home > Company Introduction

Company Overview

foshan luzhou pu machinery co.,ltd is specialized in developing ,producing and mareting different kinds of pu machines its products are sold well all over the worldproduct range:high and low pressure foaming machine,shoes soles(safety shoes) semi-automatic and full-automatic production line,sponge(memory pillow/seat mat/cushion)production line,high-temperatured elastoner machine,ear plug automatic production line,ectluzhou has its professional and unique creative designs and sale work team,luzhou has strong ability to develop new pu machines with its qualified technicians ,over 15 years experience,advances and strict testing systems.luzhou is emphasis on quality products and highly-efficient service,which has made it satisfy with customers and keep long-term bussiness with each other.meanwhile ,luzhou also provides molds and pu chemicals as long as acustoners require.

-

ManufacturerBusiness Type

-

2000Year Established

-

Above US$100 MillionAnnual Export Value

-

OthersProduct Certifications

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

21-50 People Sales Staff

-

Others Product Certifications

-

Above US$100 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

GUANG ZHOU CHINA Port of Shipment

-

Metal Processing Machinery Parts Main Industry

-

Company History1. Most of the components are imported, like the metering pump and electrical components, greatly enhancing equipment running reliability and service life; 2. The moulds can be opened and closed automatically by the pneumatic system which can save the labor cost and around 2~4 people are required for the production only. 3. The molds are heated by circulating water heating system, it can save 3/2 electricity compared with the traditional manual machine, it also makes the temperature of the molds stabler. 4. the injection can be or can not be robotic control, which is customized for the client.

Company History1. Most of the components are imported, like the metering pump and electrical components, greatly enhancing equipment running reliability and service life; 2. The moulds can be opened and closed automatically by the pneumatic system which can save the labor cost and around 2~4 people are required for the production only. 3. The molds are heated by circulating water heating system, it can save 3/2 electricity compared with the traditional manual machine, it also makes the temperature of the molds stabler. 4. the injection can be or can not be robotic control, which is customized for the client. -

Our TeamChristine Sales Manager Email: 372476020@qq.com wechat: 8618617338562 cell/whatsapp: 8618617338562

Our TeamChristine Sales Manager Email: 372476020@qq.com wechat: 8618617338562 cell/whatsapp: 8618617338562